Alstom Expands Hungarian Rail Factory: €16.2M Investment, 40% Growth

Alstom’s Expansion of its Hungarian Bogie Frame Factory: A Strategic Investment in European Rail Infrastructure

This article examines Alstom’s significant investment in expanding its railway bogie frame manufacturing facility in Mátranovák, Hungary. The €16.2 million (Ft6bn) development program represents a substantial commitment to increasing production capacity by 40%, reflecting Alstom’s strategic vision for its role in the European rail market. This expansion goes beyond simply increasing output; it involves a comprehensive modernization of the facility, incorporating advanced technologies and upskilling the workforce. The project’s implications extend beyond Alstom itself, touching upon Hungary’s national rail infrastructure development and Alstom’s broader European strategy. The integration of new technologies, the training initiatives for the workforce, and the collaborative relationship with the Hungarian government are all crucial aspects of this expansion, illustrating a model for sustainable and efficient growth in the rail industry.

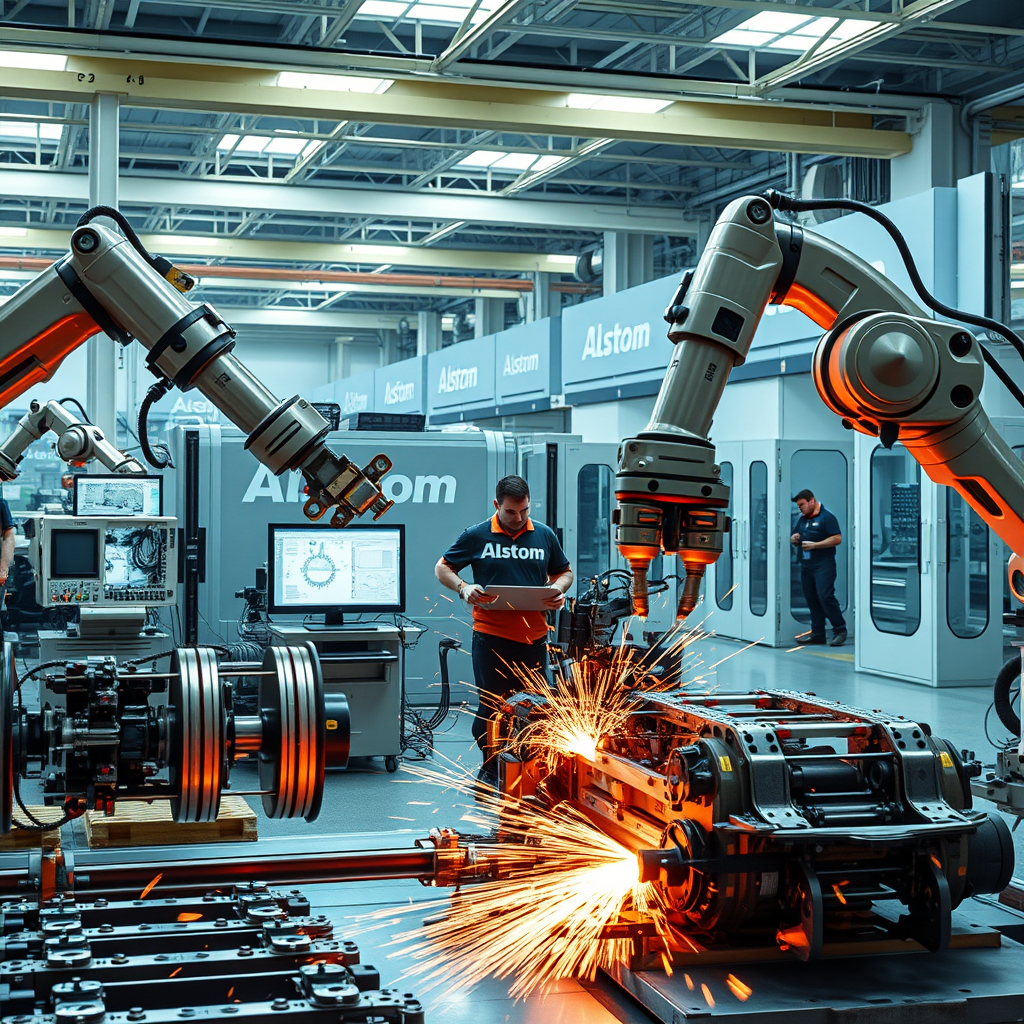

Modernization and Technological Advancement

The core of Alstom’s Mátranovák 2030 Program involves a significant upgrade of its manufacturing capabilities. This includes the installation of cutting-edge equipment such as new edge bending machines, the modernization of existing plasma cutting machines, and the integration of a new welding robot. The deployment of approximately 60 new rotators further enhances efficiency and precision in the production process. These investments in automation and advanced manufacturing techniques are not merely about increasing production volume; they are about improving quality, precision, and reducing production lead times. This strategic move positions Alstom to meet the increasing demand for high-quality railway components while maintaining competitiveness in the global market. The integration of robotics and advanced manufacturing techniques reflects a broader industry trend towards greater automation and improved efficiency within rail manufacturing.

Workforce Development and Training

Alstom’s commitment to the Mátranovák factory extends beyond technological upgrades. The company plans to hire nearly 150 new employees, spanning various roles from welders and locksmiths to CNC machine operators, engineers, and project managers. Recognizing the importance of a skilled workforce, Alstom has established an in-house welding and locksmith school at the facility. This proactive approach to workforce development is crucial for ensuring the long-term success of the expanded facility. By investing in training and upskilling its employees, Alstom not only secures a skilled workforce for its own operations but also contributes to the broader development of the Hungarian skilled labor market, aligning with the goals of the Hungarian government’s support for the project.

Strategic Partnerships and Government Support

The expansion project is a testament to the successful collaboration between Alstom and the Hungarian government. The Hungarian government’s support underlines the importance of this project to the nation’s broader infrastructure development goals and its commitment to fostering a strong domestic rail industry. This partnership extends beyond financial support; it signifies a shared vision for the future of rail transportation in Hungary and a commitment to the development of a robust and skilled workforce. This collaborative model can serve as an example of effective public-private partnerships in driving infrastructure development and economic growth in the rail sector.

The Broader Implications for European Rail

Alstom’s investment in its Hungarian facility has significant implications for the European rail industry. The increased production capacity will contribute to meeting the growing demand for railway components across Europe. The modernization efforts, incorporating advanced technologies, will enhance efficiency and quality in the manufacturing process, improving the overall competitiveness of European rail manufacturing. Furthermore, the initiative sets a precedent for other manufacturers to invest in workforce development and training, recognizing the importance of skilled labor in sustaining growth and innovation within the industry. This strategic move positions Alstom as a leader in the European rail market, driving modernization and contributing to the overall enhancement of the continent’s rail infrastructure. The success of this project will contribute not only to Alstom’s market share but also to the wider growth and sustainability of the European railway system.

Conclusions

Alstom’s expansion of its Mátranovák factory represents a significant investment in the future of European rail. The €16.2 million (Ft6bn) project, supported by the Hungarian government, will increase production capacity by 40%, leading to enhanced efficiency and competitiveness within the European rail industry. The modernization efforts, involving the implementation of cutting-edge technologies such as robotic welding and advanced CNC machinery, are crucial for meeting the growing demand for high-quality railway components. The project’s success hinges not only on technological advancement but also on the development of a highly skilled workforce. Alstom’s commitment to training and upskilling its employees through initiatives like the in-house welding and locksmith school showcases a sustainable approach to workforce management. The strong partnership between Alstom and the Hungarian government highlights the importance of collaborative efforts between public and private sectors in driving infrastructure development and economic growth. This strategic expansion signifies more than just increased production; it underscores Alstom’s commitment to technological advancement, workforce development, and sustainable growth within the European rail sector. The success of this initiative serves as a model for other rail manufacturers and a positive indicator for the future of European rail infrastructure. The project’s impact extends beyond Hungary, contributing to the overall competitiveness and efficiency of European rail manufacturing and reinforcing the importance of skilled labor in the success of large-scale infrastructure projects.