Germany’s DB: 200,000+ 3D-Printed Rail Parts, €20M+ Saved

Deutsche Bahn celebrates a decade of railway 3D printing success! Over 200,000 components deployed, saving over €20 million. Revolutionizing rolling stock maintenance.

Deutsche Bahn (DB) is celebrating a decade of pioneering additive manufacturing, reporting over 200,000 3D-printed components now in active service and a substantial cost saving exceeding EUR 20 million since 2015. This milestone underscores the railway giant’s transformation of its rolling stock maintenance through advanced digital and manufacturing strategies.

| Key Entity | Critical Detail |

|---|---|

| Main Company/Location | Deutsche Bahn (DB), Germany |

| Core Action | Celebrating 10 years of additive manufacturing, deploying over 200,000 3D-printed parts. |

| Budget/Value | Saved over EUR 20 million since 2015. |

| Date/Timeline | Additive manufacturing use began in 2014; reporting milestone in 2024. |

Strategic Impact

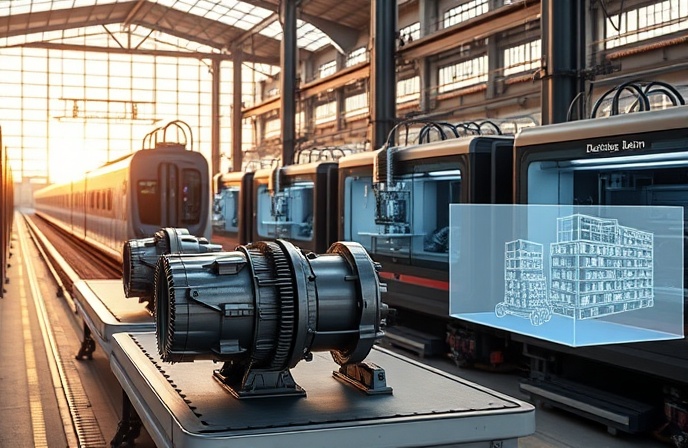

What began a decade ago with small, functional plastic items such as coat hooks has evolved into a sophisticated application of 3D printing across Deutsche Bahn’s extensive operations. The company now boasts a catalogue of over 1,000 distinct 3D-printed applications, spanning from intricate, lightweight fittings to substantial metal components, including a notable 540-kilogramme gearbox housing. DB views 3D printing not merely as a technical solution, but as a cornerstone of its strategy to enhance the reliability, sustainability, and cost-effectiveness of its vast rolling stock maintenance program. This commitment positions DB as a global leader among railway operators in the large-scale deployment of additive manufacturing.

Operational Excellence

The primary application of this technology at DB lies in the production of critical spare parts for trains and locomotives, particularly for components that are no longer in serial production or for which timely supplier delivery is problematic. This on-demand manufacturing approach significantly reduces the need for extensive inventory, thereby minimizing storage space and associated logistics costs, while concurrently accelerating delivery times. This enhanced flexibility is instrumental in mitigating risks associated with supply chains that often face challenges in providing legacy components, ensuring greater operational continuity.

At the heart of DB’s digital maintenance strategy is its Digital Parts Warehouse, an extensive database containing technical drawings and virtual models of over 1,000 items. This centralized repository allows maintenance workshops to easily access digital files, enabling parts to be produced either internally or through DB’s established network of specialized partners. Stefanie Brickwede, Head of DB’s Group 3D Printing Project, highlighted the direct impact: “With the help of 3D printing, we can make necessary spare parts available literally at the push of a button. Our customers benefit from this, as we get trains back on the tracks faster. At the same time, we support our employees, who can work more efficiently.”

While repairs constitute a significant portion of 3D-printed component usage, DB is also integrating additive manufacturing into the deployment of new rolling stock. For instance, the new ICE L trains utilize a specifically designed 3D-printed yellow template. This tool aids staff in accurately and efficiently applying pictograms and QR codes during the onboard fit-out process, reportedly leading to reductions in labor time and costs during the preparation of these new high-speed trains.

Technical Specifications

- Number of 3D-printed components in use: Over 200,000

- Catalogue of applications: Over 1,000

- Largest metal component printed: 540-kilogramme gearbox housing

- Number of 3D printing processes employed: Twelve (including material extrusion, powder-bed fusion, and binder jetting)

- Materials used: Plastic, metal, and sand

- Size of Digital Parts Warehouse: Over 1,000 digital models

Industry Context

Deutsche Bahn’s decade-long commitment to additive manufacturing and its successful integration into core maintenance and fleet rollout processes serve as a compelling case study for the global railway industry. The company’s substantial cost savings and operational efficiencies demonstrate the tangible benefits of embracing advanced digital manufacturing technologies. By alleviating supply chain dependencies, accelerating repair times, and fostering innovation, DB is setting a benchmark for how railways can leverage 3D printing to enhance asset longevity, reduce operational expenditure, and ensure greater service reliability for passengers. Furthermore, DB’s proactive role in establishing the “Mobility goes Additive” network, which now comprises over 140 organizations, highlights a broader industry-wide effort to advance and standardize industrial 3D printing solutions, indicating a significant shift towards more agile and sustainable manufacturing paradigms within the sector.