China’s Intelligent Tunnel: A High-Speed Rail Revolution

This article explores the groundbreaking advancements in intelligent shield tunneling technology showcased in the construction of the Chongtai Yangtze River Tunnel, a critical component of the Shanghai-Chongqing-Chengdu High-Speed Railway (HSR) project. The successful implementation of this technology represents a significant leap forward in the efficiency, safety, and precision of underwater tunnel construction. The project’s scale and complexity, coupled with its location beneath one of the world’s busiest and deepest rivers, underscore the challenges overcome and the technological prowess demonstrated. This deep dive will analyze the key technological innovations employed, the operational strategies implemented, and the broader implications for the future of high-speed rail infrastructure development globally. We will also examine the tunnel’s unique design parameters, its role in regional connectivity, and the potential impact on China’s Belt and Road Initiative.

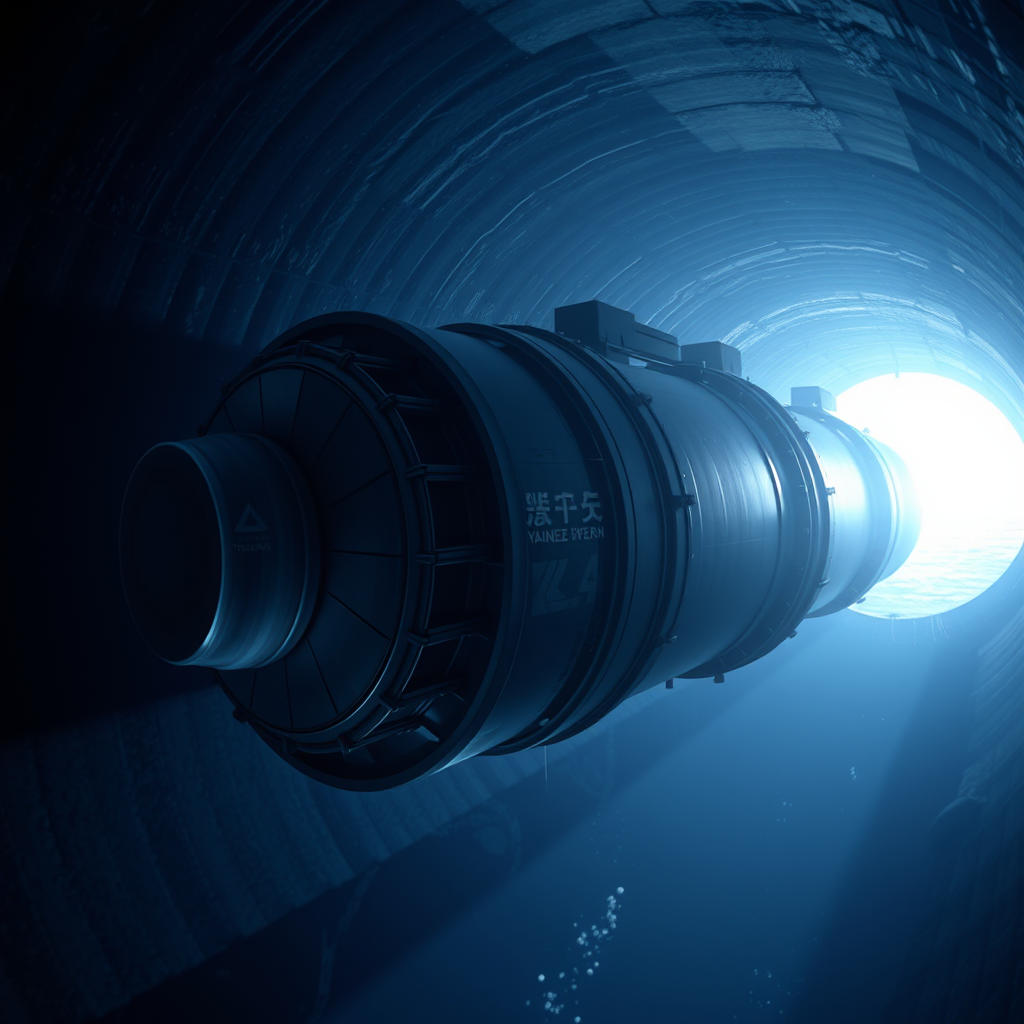

Intelligent Tunneling Technology: A Paradigm Shift

The Chongtai Yangtze River Tunnel project has successfully deployed an intelligent shield tunneling system (version 2.0) for the “Pioneer” tunnel boring machine (TBM). This system enabled “attended but unmanned” operation, a significant achievement in automated construction. The system incorporates advanced sensors, AI-driven decision-making algorithms, and remote monitoring capabilities, allowing for precise control of the TBM even in the challenging conditions of underwater excavation. This eliminates many human-error risks and significantly increases the overall efficiency of the boring process. The automated system continuously monitors ground conditions, adjusts cutting parameters in real-time, and optimizes the overall excavation process, leading to increased speed and accuracy.

Overcoming the Challenges of Underwater Construction

Constructing a tunnel beneath the Yangtze River presented numerous significant challenges. The river’s depth and the high water pressure (maximum 0.9 MPa) demanded robust engineering solutions and advanced safety protocols. The project also incorporated stringent environmental safeguards, notably the protection of the Yangtze River knifefish germplasm resources. The successful navigation of the TBM through this sensitive area underscores the careful planning and precise execution of the project. The single-hole double-track design, with a 15.4m shield diameter and 14.8m outer tunnel segment diameter, represents a significant engineering feat and marks a new standard in the design and construction of high-speed rail underwater tunnels.

Optimizing Efficiency and Precision

The project’s success hinges not only on the sophisticated tunneling technology but also on the integration of intelligent manufacturing processes. An intelligent factory was established for the automated production of tunnel segments, ensuring consistent quality and minimizing delays. This streamlined approach to construction contributes to the overall efficiency of the project, reducing both costs and construction timelines. The optimized workflow, from segment production to TBM operation, significantly improved project quality control and reduced potential errors.

Strategic Significance and Future Implications

The Chongtai Yangtze River Tunnel is more than just a transportation link; it’s a testament to China’s commitment to technological advancement and infrastructure development. The tunnel, designed for trains operating at 350 km/h, will drastically reduce travel times between Shanghai and Nanjing metropolitan areas, fostering economic integration and facilitating regional development. Its completion further strengthens China’s high-speed rail network and aligns with the goals of the Belt and Road Initiative, promoting connectivity across Asia and beyond. This project showcases the successful application of cutting-edge technology to solve significant engineering challenges, setting a precedent for future large-scale infrastructure projects globally.

Conclusions

The successful completion of over 2.6 km of autonomous excavation in the Chongtai Yangtze River Tunnel using the intelligent shield tunneling system (V2.0) represents a major advancement in the field of railway engineering. The project highlights the synergy between intelligent tunneling technology, advanced manufacturing techniques, and robust project management. The integration of AI-driven decision-making, real-time monitoring, and automated segment production significantly improved efficiency, precision, and safety, showcasing a new paradigm for underwater tunnel construction. The tunnel’s design parameters – including its impressive diameter, speed capacity, and single-hole double-track configuration – redefine the benchmarks for high-speed rail underwater tunnels globally. Beyond its immediate impact on regional connectivity and economic development in the Yangtze River Delta, the Chongtai Yangtze River Tunnel project provides valuable insights and sets a new standard for future high-speed rail infrastructure projects worldwide. The advancements demonstrated here will undoubtedly influence the design and construction of similar projects globally, accelerating the development of faster, safer, and more efficient high-speed rail networks in diverse geographical settings. The project underscores the potential of integrating innovative technologies to address complex engineering challenges and the transformative power of such advancements in shaping global infrastructure and connectivity.