Alstom’s €150M Avelia Expansion: High-Speed Rail Revolution

Alstom’s Significant Investment in Avelia High-Speed Train Production: A Strategic Expansion

This article examines Alstom’s substantial €150 million ($164.4 million) investment to bolster its Avelia high-speed train production capabilities across multiple French facilities. This strategic move reflects the burgeoning global demand for high-speed rail solutions and Alstom’s commitment to solidifying its position as a leading player in this rapidly expanding sector. The investment encompasses not only increased production capacity at existing sites but also the establishment of new assembly lines, leveraging cutting-edge technologies to enhance efficiency and product quality. Further, the plan involves significant workforce expansion and supply chain improvements, underscoring the far-reaching implications of this initiative for both Alstom and the French economy. We will explore the specific enhancements planned for each facility, the technological advancements implemented, and the overall strategic implications of this ambitious undertaking.

Expanding Production Capacity and Geographic Reach

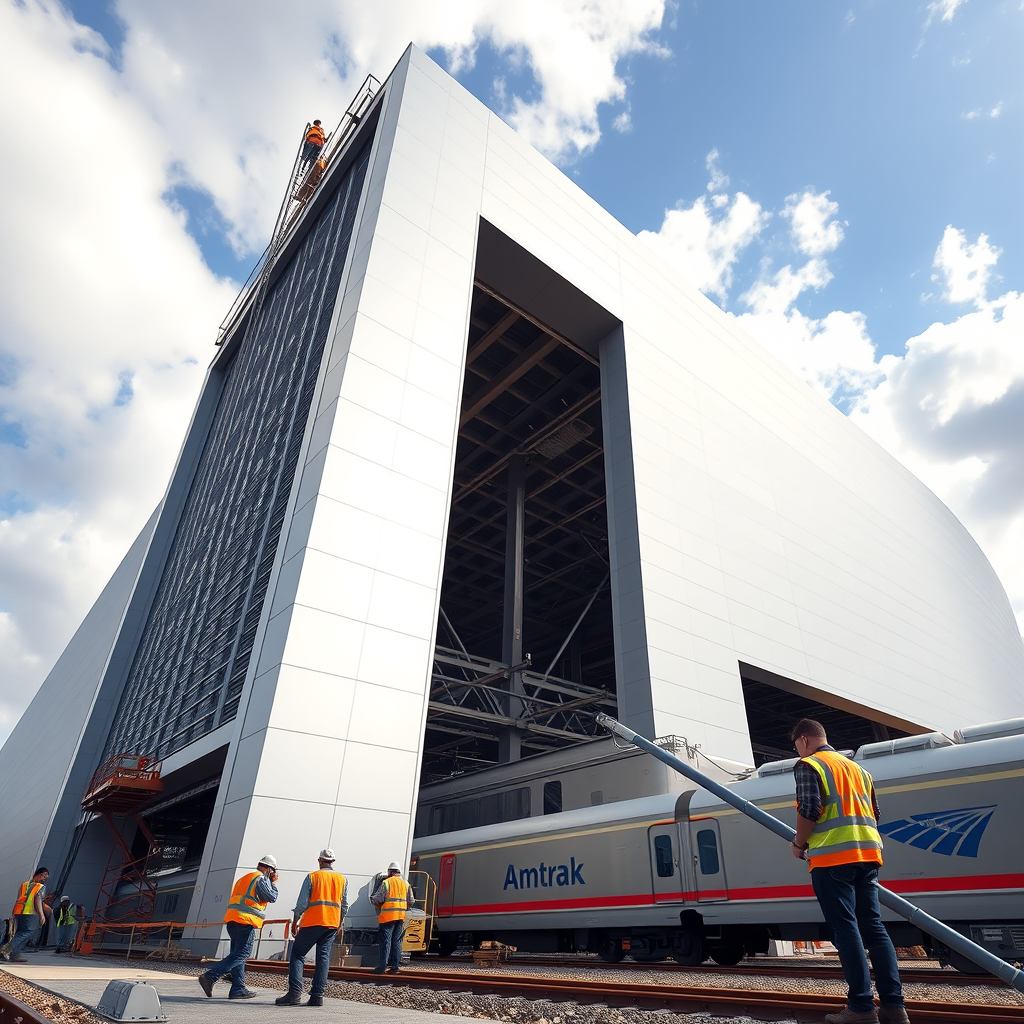

Alstom’s investment strategy focuses on strategically expanding its production capacity to meet the growing demand for its Avelia high-speed trains. A key component of this is the creation of a new assembly line at the Valenciennes Petite-Foret site, a significant expansion into a new northern French location. Simultaneously, the existing La Rochelle facility will see a doubling of its carbody shell and assembly lines. This dual approach not only increases overall production volume but also diversifies Alstom’s manufacturing footprint, reducing reliance on single sites and mitigating potential risks associated with localized disruptions. The expansion utilizes lean manufacturing principles, optimizing resource utilization and minimizing waste throughout the production process. This commitment to efficiency ensures that Alstom can effectively scale its operations to satisfy current and future market demands.

Technological Advancements and Digital Transformation

Alstom’s investment extends beyond mere capacity expansion; it is intrinsically linked to the integration of advanced technologies. The company’s commitment to digitalization and simulation is exemplified by its investment in facilities like the TrainLab in La Rochelle. This state-of-the-art facility utilizes sophisticated simulation technologies to drastically reduce the time required for new train testing and validation, accelerating the product development lifecycle and allowing for faster market response. Moreover, investments in component manufacturing sites (Petit Quevilly, Ornans, Tarbes, and Le Creusot) focus on adopting robotic automation and advanced welding technologies, improving production speed, precision, and safety. This demonstrates Alstom’s embrace of Industry 4.0 principles, using data-driven insights to optimize processes and improve overall manufacturing efficiency.

Strengthening the Supply Chain and Workforce

Recognizing the crucial role of its supply chain, Alstom is investing directly in its suppliers to ensure they can support the company’s ambitious growth targets. This proactive approach helps to secure a reliable and responsive supply chain, mitigating potential bottlenecks and supply chain disruptions. Furthermore, the investment is projected to generate at least 1,000 new jobs directly within Alstom, with an additional 2,500 jobs created or secured within the company’s French supply chain network. This significant job creation has a considerable positive impact on the French economy, further strengthening Alstom’s position within the national industrial landscape.

Conclusions: A Strategic Investment with Far-Reaching Implications

Alstom’s €150 million investment in expanding its Avelia high-speed train production represents a strategic move with far-reaching consequences. The expansion of existing facilities, coupled with the establishment of new assembly lines in Valenciennes, signifies a substantial increase in production capacity designed to meet the escalating global demand for high-speed rail solutions. This expansion is not just about scale; it is fundamentally about technological advancement. The integration of Industry 4.0 principles, through digitalization, simulation (such as the TrainLab), robotization, and advanced welding techniques, drastically improves efficiency and reduces time-to-market. The significant job creation—both within Alstom and its supply chain—underscores the positive economic impact of this initiative, reinforcing Alstom’s role as a key player in the French economy. Furthermore, the investment in the supply chain ensures the long-term viability and robustness of Alstom’s production capabilities. In summary, Alstom’s strategic investment is not just about producing more trains; it’s about building a more efficient, technologically advanced, and economically sustainable future for high-speed rail transportation. This commitment positions Alstom favorably to capitalize on the growing global demand for high-speed rail, securing its position as a leader in the industry for years to come. The successful execution of this plan will solidify Alstom’s market dominance and establish a benchmark for innovation and sustainable growth within the railway sector. This comprehensive approach to expansion, incorporating technological innovation, supply chain integration, and significant job creation, represents a model for responsible and forward-thinking growth in the global railway industry.